There's many advantages to making a paddle yourself. Maybe you just completed a strip built project canoe and would like a matching paddle. Or maybe conventional store bought paddles just don't fit your hands right. Whatever your reason a custom made paddle may be the answer. You can adjust the length, blade size, grip diamater, and dimention to fit you exactly providing a much better paddling experience.

The top two questions asked are:

1) How much will it cost?

2) How hard is it to do?

The simple answers are:

1) Much lower than a store bought one.

2) If you can paddle a canoe, you can build your own paddle.

First lets cover cost. Many people may be suprised that it can be done for so little and expect a compromise. These instructions will be using Pine which is one of the heavier, but stronger woods but lighter woods can be substuited and the paddle completed in the same way. Don't be put off by the weight of pine though. A pine paddle is a good choice for durability and won't be akwardly heavy if made correctly.

It is also assumed you own or can borrow any tools needed. The list is small and you can improvise on some of the tools and still obtain the end result.

Second comes the matter of diffucilty. Many assume you need to be a professional woodworker to get professional results. While a woodworking background is helpful it is in no way required. Learning as you go may take a bit longer, but the end result will be worth your time. And there's no satisfaction like using a paddle you made yourself.

Enough with the preamble lets get down to business. Here is a list of the supplies you will need:

A. Consumables

1) A 2x4 from your local lumber yard or box store (Lowe's, Home Depot, ect..)

2) Quality *waterproof* wood glue or epoxy.

3) Sandpaper

I only use and recomend Titebond III waterproof wood glue. You can buy this is small quantites for as little as $2-3.

B. Tools

1) Table saw/Band saw or access to one to rip 5 strips.

2) An assortment of clamps

3) Measuring Tape

4) Block Plane, Draw Knife, or Spoke Shave (1 or all 3)

5) File. Preferbaly a wood rasp. A file meant for metal is useable but will take much longer.

6) A Jig Saw or Hand Saw

C. Other

1) Space to clamp up and carve the paddle.

2) An area outside to varnish the finished paddle.

Before getting started i'll cover one of the most important factors influiencing this project, selection of a suitable 2X4. This may seem simple but once you get to the store you don't want to grab the first one on the pile. You want to look for a board with as few knots or defects as possible. You also want to look down the length of the board and find one as straight as possible. Sometimes I may spend 10-15 minutes digging thru the pile to find a suitable board but it's that important if you want as a high a quality paddle as possible.

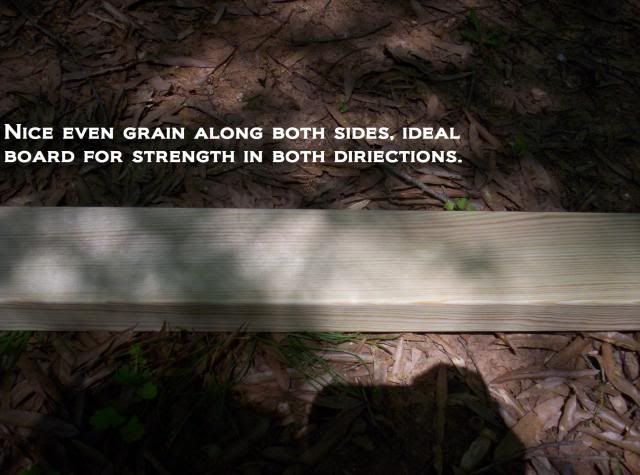

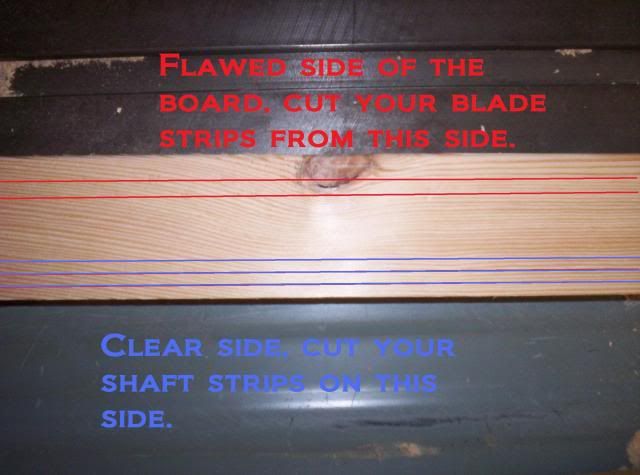

You also want to pay attention to the grain in the board. Idealy you would find a board with tight grain along the 2" side so when cut it provides strength in the direction the paddle will flex.

If you have trouble finding a suitable 2X4 check the 2X8 and 2X10 sections. Usually the larger boards are cut from larger trees and it's easier to find one with minimal defects or at least an area large enough thats defect free for the project.

The board I use in this example is a 2X4X96" from my local Lowes bought for $3.15. It has nice grain along both sides with only one defect, providing plenty of clear board for the shaft strips.

The first step is to rip 5 lengths off the board.

-Three .275 wide strips (just over 1/4)

-One .600 strip (5/8ish)

-One .415 strip (little less then 1/2)

The .275 strips will be stacked to a height of 4 strips for a total of around 1 1/8". If your wanting a larger or smaller grip vary the thickness on them to 1/4 your desired height. I'll be making mine a standard 1 1/8" x 1 1/4" but feel free to vary any of the dementions if you know your after a specific size.

Next cut the 5 strips into 1.25" width or your personal desired width.

Now onto the jig for making a bent shaft. If your making a striaght shaft paddle skip this section.

Most of you wont have a protractor laying around but don't worry, you won't need one to make the correct angle. Here is a step-by-step guide on how to find a 15 degree angle with nothing but a ruler and a straight edge.

Start by measuring in from the edge the distance that your blade will be. In my example i'm making an 18" blade so at 18" I make a line perpendicular to the scrap woods edge.

Then place your ruler at about 45 degrees to the bottom edge as show and make a mark at 1/3 the distance. What this means is I lined up my tape measure so at 45 degrees the length was 6 inches. 2 inches is 1/3, or 30 degrees of the original 90 degree angle.

Then do the same to cut the 30 degree in half, for a 15 degree angle. Connect this point with your 90 degree base point and now you have a 15 degree wedge.

Remeber all that usless geometry you learned in 9th grade and forgot? Bet you never know you'd need it to make a canoe paddle!

Next we'll take the three .275 strips we cut earlier and shorten them to shaft length. For making a bent shaft add 2" to your desired length. This accounts for the fact that the bend moves both ends slighly closer to eachother shortining the overall length (again 9th grade math to the rescue).

In my example i'm making a 52" paddle, so I cut all 3 boards to 54". I then use one of the leftover peices that is 44" long as my 4th shaft strip, bringing my total thickness to my target of 1 1/8".

No comments:

Post a Comment